|

|

|

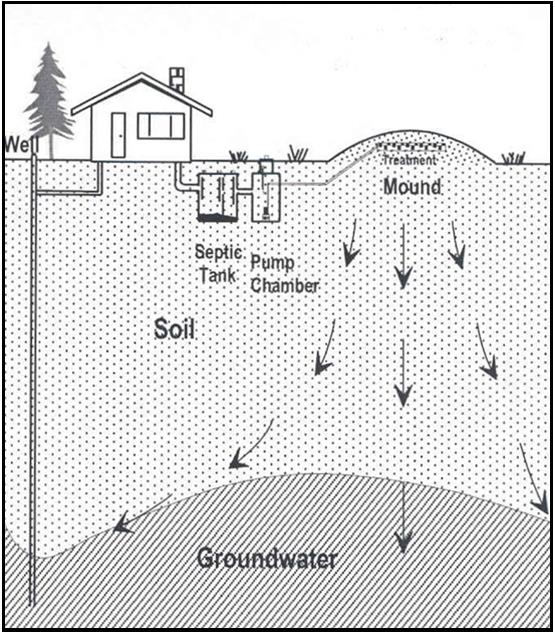

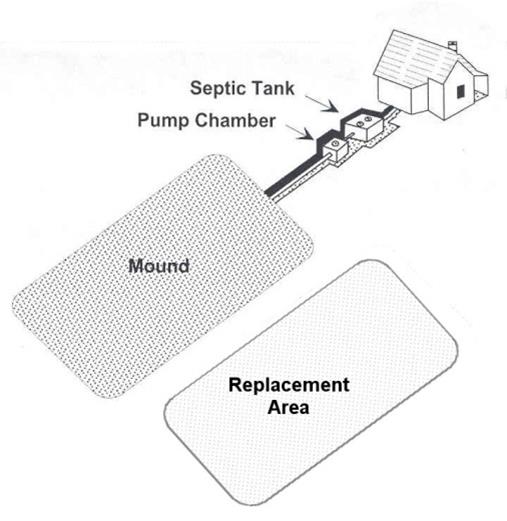

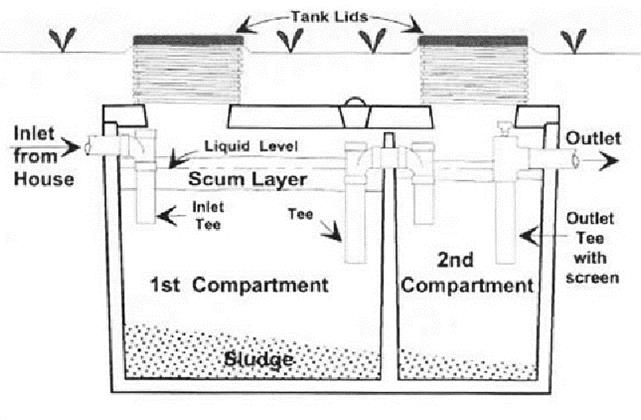

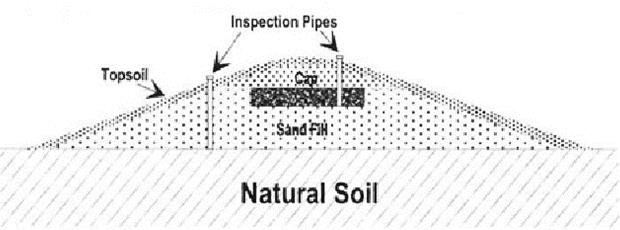

Septic tanks with gravity flow drainfields have been used for many years in areas not served by public sewers. Unfortunately, not all soil and site conditions are well suited for these standard systems. To protect public health and water quality, non-standard systems are often used in areas where standard systems cannot assure safe sewage treatment. A mound system is one type of non-standard system which provides: * Dosing and resting cycles * Uniform distribution of effluent * Known level of sewage treatment * Greater distance for effluent to travel before reaching groundwater The following information will help you understand your mound system, and keep it operating safely at the lowest possible cost. A typical mound system has 3 working parts: * The septic tank * The pump chamber and pump * The mound with its replacement area The Septic Tank The typical septic tank is a large dual-chambered buried container made of concrete, fiberglass or polyethylene. Wastewater from your home flows into the tank. Heavy solids settle to the bottom where bacterial action partially decomposes them. Most of the lighter solids, such as grease and oils, rise to the top and form a scum layer. A liquid layer exists between the solids layers and passes from one chamber to another.  The wastewater leaving the septic tank is a liquid called effluent. It has been partially treated but still contains disease-causing bacteria and other pollutants. From the tank, the effluent flows by gravity to the pump chamber. Proper Care Includes: 1. Inspecting your septic tank once every year and pumping it when needed. If the tank is not pumped periodically, solids escaping from the septic tank will clog the pump and mound. The use of a garbage disposal is highly discouraged because it will increase the amount of solids entering the tank and require more frequent pumping. 2. Avoiding the flushing of harmful material into the septic tank. Never put materials such as grease, cooking oils, newspapers, paper towels, cigarette butts, coffee grounds, diapers, sanitary napkins, solvents, oils, paint or pesticides into the tank. 3. Avoiding the use of any type of chemical or biological septic tank additive. Such products are not necessary for the proper functioning of a septic tank, nor do they reduce the need for routine tank pumping.  The Pump Chamber The pump chamber is a concrete, fiberglass or polyethylene container that collects the septic tank effluent. The chamber contains a pump, pump control floats and a high water alarm float. The pump action can be controlled either by the use of control floats or by timer controls. Control floats are set to turn the pump on and off at levels for pumping a specific volume of effluent per dose. Timer controls are set to produce both the length of the dose and the interval or rest period between doses. The high water alarm float starts an alarm to warn you of any pump malfunction. If pump timer controls are used, the alarm also will warn you of excessive water use in the home or leaks into the system. The float is set to start when the effluent in the pump chamber rises above the on/off float. The alarm should consist of a buzzer and an easily visible light. It should be on an electrical circuit separate from the pump. The pump discharge pipe should have a union and valve for easy removal of the pump. A piece of nylon rope or other non-corrosive material should be attached to the pump for taking the pump in and out of the chamber. Proper Care Includes: 1. Checking the pump chamber, pump and floats every year and replacing or repairing worn or broken parts. Pump maintenance should follow the manufacturers recommendations. Check electrical parts and conduits for corrosion. If the alarm panel has a push-to-test button, it should be utilized regularly. 2. Installing a septic tank effluent filter or pump screen, if your system does not have one. Screening or filtering the septic tank effluent provides an effective way of preventing solids from clogging the pump and pipes. Inspecting the filter and cleaning it when necessary is quick and easy, and prevents costly damage from solids entering the system. 3. Taking action to protect the mound from overloading after a prolonged power outage or pump failure. Effluent will continue to collect in the pump chamber until the pump starts operation. With additional effluent in the chamber, the pump may dose a volume more than the mound can handle. Once the reserve storage in the chamber is all used up, the plumbing in your home can backup. When the pump is off for more than 6 hours, reduce your water use to a minimum.  The Mound The mound is a drainfield that is raised above the natural soil surface in a specific sand fill material. Within the sand fill is a gravel-filled bed with a network of small diameter pipes. Septic tank effluent is pumped through the pipes in controlled doses to insure uniform distribution throughout the bed. The effluent leaves the pipes under low pressure through small diameter holes, and trickles downward through the gravel and into the sand. Treatment of the effluent occurs as it moves through the sand and into the natural soil. Every new mound is required to have a designated replacement area. It must be protected should the existing system need an addition or repair. Proper Care Includes: 1. Knowing where your system and replacement area are located and protecting them. Before you plant a garden, construct a building or install a pool, check on the location of your system and replacement area. 2. Practicing water conservation and balancing your water use throughout the week to keep from overloading the system. The more wastewater you produce, the more the mound must treat and dispose. 3. Diverting water from surfaces such as roofs, driveways or patios away from the mound and replacement area. The entire mound is graded to provide for runoff. Place structures, ditches and driveways far enough away so that water movement from the mound is not disrupted. 4. Keeping traffic, such as vehicles, heavy equipment or livestock off the mound and replacement area. The pressure can compact the soil or damage pipes. 5. Landscaping your mound properly. Do not place impermeable materials over your mound or replacement area. Materials such as concrete or plastic reduce evaporation and the supply of air to the soil needed for proper effluent treatment. Grass is the best cover for the mound. 6. Inspecting the mound and downslope areas for odors, wet spots or surfacing sewage periodically. Check your mound systems inspection pipes regularly to see if there is a liquid level continually greater than 6 inches. This may be an early indication of a problem. What If The Alarm Goes On? If, for any reason, the effluent level inside the pump chamber reaches the alarm float (faulty pump, floats, circuit, excessive water use or another problem), the alarm light and buzzer will start. By using water conservatively (avoid baths, showers and clothes washing), the reserve storage in the pump chamber should allow you enough time to get the problem corrected. To silence the alarm, push the reset light on the alarm panel. Before calling for service or repair, check to see if the problem could be: 1. A tripped circuit breaker or blown fuse. The pump should have a separate circuit with its own breaker or fuse. If it is on a circuit with other equipment, that equipment can cause the breaker to trip. 2. A pump or float switch power cord that has come unplugged. If electrical connections are the plug-in type, be sure switch and pump plugs are making good contact in their outlet. 3. Control floats tangled by other parts in the chamber such as the electric power cord, lifting rope or pump screen. Be sure floats operate freely in the chamber. 4. Debris on floats and support cable that is causing the pump to switch off. Lift the floats out of the chamber and clean. CAUTION: Always turn off the power supply at the circuit breaker and unplug all power cords before handling the pump or floats. Do not enter the pump chamber. Gases inside pump chambers are poisonous and the lack of air can be fatal. If the problem cannot be located with the above steps, call your pump service person or on-site system contractor for service or repair. An experienced person must do the service or repair of pumps and other electrical equipment. |

|

|

|

It is a common misconception that a real estate agent primarily learns of someone looking to buy or sell a home when someone simply calls an agency looking for an agent to help them. Although this can happen, it is very rare. In fact, over 80% of the referrals I receive come from past clients and past coworkers just like you. The other 15-20% of referrals comes from our national network of relocation companies and other Coldwell Banker agencies across the country. The greatest compliment I can receive is when someone like you refers me to a friend, coworker or family member of theirs. If you, or someone you know, are looking to either buy or sell a home then I would certainly appreciate the opportunity to earn your business. Do you know of someone looking to buy or sell a home?  Click the vCard below to download my contact information to load on your phone and to share with anyone you know that would benefit from my help in buying or selling a home.

|

|

|

12401 Old Meridian Street Carmel, In 46032 Email brad@btgough.com Mobile (317) 590-3571 Office (317) 844-1131 Website www.btgough.com |